Just so versatile and quick for all the little odds/ends type jobs that go along with gun plumbing. Bench barrels and other guns that need a short tube can be supported from both ends without any sort of head scratching or brain damage.īUY ONE if at all possible as it's the only way to go short of a CNC IMO. The other big benefit with this is the short headstock distance. Ditch the tail stock for cramming the reamer and use the carriage, much easier IMO and the tail stock gets in the way for inserting removing long barrels anyway.

VERY quick set ups and very, very nice results. Make your spider with a split collar and it will clamp on/off real easy on the back side with a single socket cap screw. Just stick a four jaw on the spindle nose and you get enough offset so that the cylinder portion of the barrel never goes inside the spindle bore. I did a whole pile of tomato stakes with theirs as an interim solution when we were waiting for the Harrison Alpha 1330U to arrive. Web site will assume no responsibilities for damages or injuries resulting fromĢ021 (formerly owwm.If this is the same machine Dakota Arms/Nesika has (and I am pretty sure it is) then it will work just fine for chambering barrels.

Good judgment and to safely operate old machinery. Themselves may not meet modern standards.

Rebuilding hardinge hlv h lathe manuals#

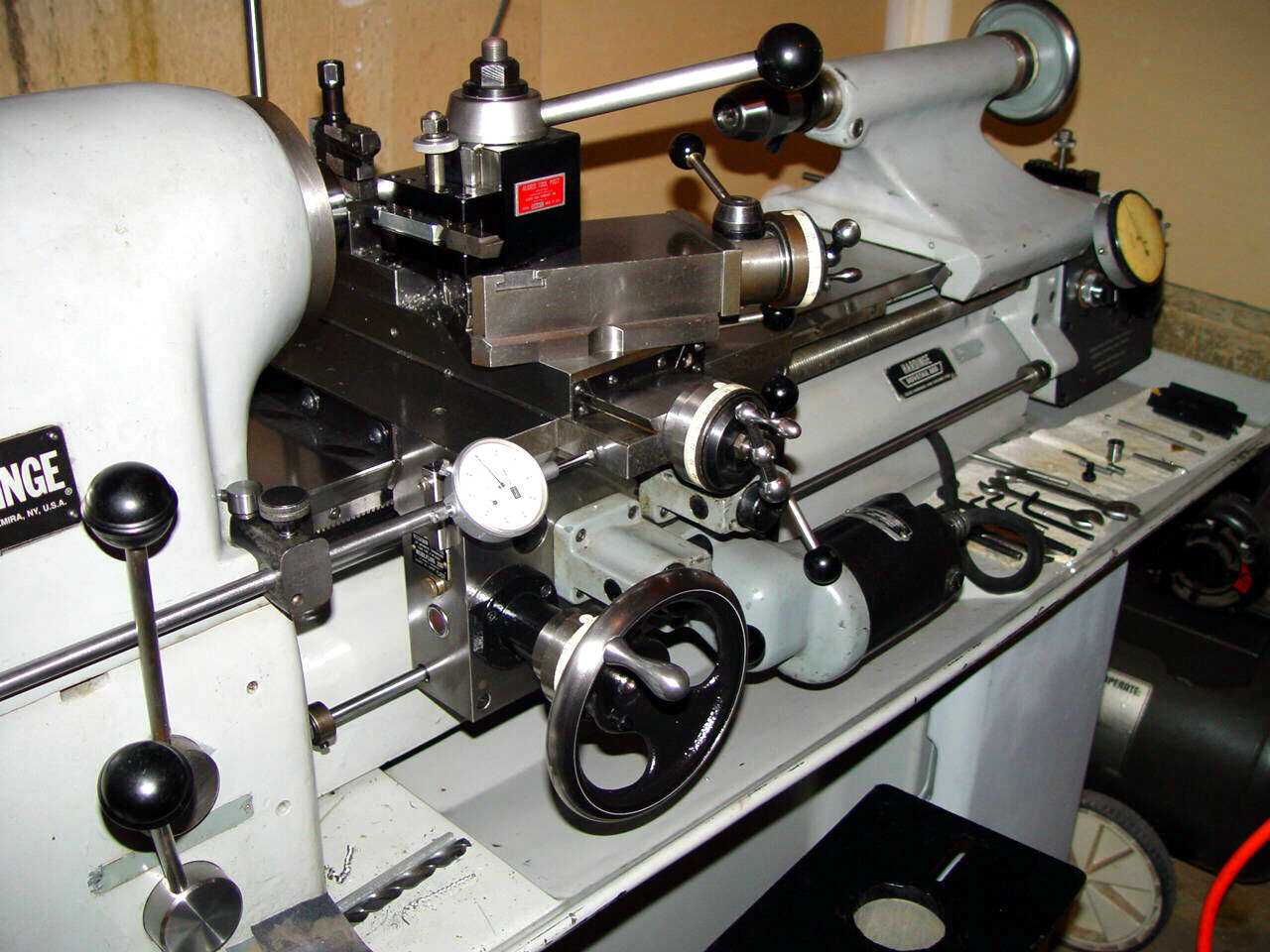

Please remember that safety standards haveĬhanged over the years and information in old manuals as well as the old machines This would be 600 rpm and 1800 rpm at 60 Hz. It starts with a 3-phase, two speed squirrel cage induction motor, rated at 500 rpm and 1500 rpm nominal (less in practice, due to slip) at 50 Hz. On this site nor do we represent any manufacturer listed on this site in any way.Ĭatalogs, manuals and any other literature that is available on this site is madeĪvailable for a historical record only. All Hardinge HLV and HLV-H variants feature a continuously variable speed drive to the spindle. does not provide support or parts for any machines Our purpose is to provide information about vintage machinery that is generallyĭifficult to locate.

Rebuilding hardinge hlv h lathe professional#

PLEASE NOTE: was founded as a public service toĪmateur and professional woodworkers who enjoy using and/or restoring vintage machinery.

0 kommentar(er)

0 kommentar(er)